Follow us on Twitter:

@yardbirdcom

Comments

The Meltdown

A novelBuy paper or ebook editions

Buy a paper copy $15 >

Buy for all ebook readers - $7.99

The Meltdown

Time plays tricks in Unit 2Time is playing tricks in the control room of Three Mile Island's Unit Two.

For the men working there at 6:20 am, time seems to have gone haywire.

First the stream of time increased its speed, then it stood still and reversed.

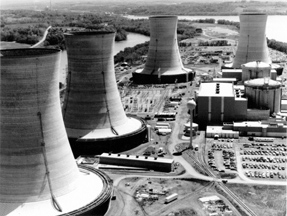

It's 4 o'clock in the morning, March 28, 1979. Unit One on Three Mile Island has been in commercial operation since September 2, 1974. Unit Two, since December 30, 1978 -- only three months earlier.

Workers point into Unit One reactor on Three Mile Island. The reactor head is seen in the background.

Today is an anniversary of sorts for Unit Two. Exactly one year before, on March 28, 1978, the control rods, surrounding the 159.3 tons of uranium fuel assemblies, were experimentally lifted away and the nuclear chain reaction began. But one year later, at 4:00 am, there is no celebration on Three Mile Island.

In fact, things are pretty still. Unit One is down for refueling, scheduled to come back on line within the week.

Far from the placid east shore of the Susquehanna River, in the spacecraft-like control room of Unit Two, work two men, Ed Frederick and Craig Faust. They're working the graveyard shift, monitoring the functions of the nuclear reactor. It's quiet in the brightly lit control room.

A few seconds after 4:00 am, the turbine that generates Unit Two's electricity trips, or shuts down. The secondary feedwater flow, used to turn the turbine, is stopped.

Time, and energy, suddenly are playing violent tricks in the massive and labrynteen Rube Goldberg plumbing of the atomic power plant. The men who work in the control room suddenly will be like clueless ants atop a charging rhino.

The heat produced from the nuclear core is carried by water to two mammoth steam generators where the heat is exchanged to a secondary feedwater system. Inside the steam generators, water from the secondary feedwater system is turned into steam which drives the turbine.

When the turbine shuts down, the secondary feedwater supply no longer carries heat away from the steam generators and the water cooling the atomic reactor begins to overheat rapidly. Within seconds, a pressure relief valve atop a gigantic piece of equipment called a pressurizer opens, as it should, to relieve the mounting pressure, like the top of a tea kettle. The water rushing from this valve creates a tremendous whistling sound.

Inside the control room Faust and Frederick know something has gone wrong. Within seconds, several hundred ringing and flashing alarms go off. Hearing the blast of water escape the pressurizer's relief valve, they're sure the turbine has shut down.

Inside Unit 2 control room, operators discuss problems in the days following the 1979 accident. Notice that two operators are smoking cigarettes.

The two men monitor the reactor's computer as it automatically commands Unit Two's control rods to slip down among the uranium fuel, scramming, or stopping, the nuclear chain reaction. Within fifteen seconds after the pressure relief valve opens, the pressure returns to its normal 2,205 pounds per square inch, and the computer commands the valve to close. But, unknown to the men in the control room, the valve does not respond to the command and remains open.

Water under tremendous pressure continues to pour from the pressurizer into a wastewater storage tank in the reactor containment building.

The computer is programmed to assume that the valve on top of the pressurizer will close at the proper time. When that does not happen, in its electronic way, the computer becomes confused. To add to the mix-up, a gauge in the control room indicates to Faust and Frederick that the pressurizer is quickly filling with water when in fact, water is rushing out of the pressurizer.

Things begin to happen quickly for the two men in the control room of Unit Two. Forty seconds after the turbine first trips, the computer directs the auxiliary feedwater system to turn on. Because the secondary feedwater flow is stopped, the auxiliary feedwater system is needed to carry heat away from the steam generators. Between the three pumps of the auxiliary feedwater system and the steam generators, however, two valves are closed, blocking the flow of water. One important emergency system is useless. The computer and the operators do not know about this either, and the computer begins to lose control of the nuclear power plant.

One minute into the accident: the steam generators are boiling dry, and the core begins to heat rapidly.

Even though the reactor has been scrammed, the nuclear core is still generating a tremendous amount of heat, and is boiling dry.

Two minutes after the initial turbine trip, the computer activates the emergency core cooling system pumps -- yet another set of pumps designed to avert catastrophe. These pumps are meant to switch on should the reactor's normal coolant pumps fail, or if there is a sudden loss of pressure. The emergency core cooling system pours thousands of gallons of water directly through the core at 1,600 pounds per square inch.

Unit 2 reactor in transit while plant was under construction.

In the control room, meanwhile, Frederick is watching the malfunctioning pressurizer gauge go off scale. Normally, the pressure in the reactor's primary loop is controlled by means of a steam bubble inside the pressurizer: the bubble acts like a shock absorber. The gauge incorrectly tells Frederick that the pressurizer is filling with water, its steam bubble disappearing.

Actually, the water level is dropping, as coolant is now seeping through the stuck relief valve at the pressurizer's top, through piping, into a storage tank. But believing this gauge reading to be accurate, Frederick fears that the pressurizer may soon be packed solid with water. Trained to avoid a "solid system," he imagines that the primary coolant might back up into the much-needed emergency core cooling system pumps and cripple them.

Not yet four minutes into the mishap, Frederick begins to throttle down the emergency core cooling system pumps, fearing they are dumping too much water into the system. In fact, they are the only thing keeping the nuclear reactor from melting.

Foiled at first by a pressurizer relief valve that would not close, second by the auxiliary feedwater flow being valved off, and finally by Frederick shutting down the emergency core cooling system pumps, the computer crashes. The men in the control room of Unit Two are now flying a runaway nuclear power plant by the seats of their pants.

Faust and Frederick are sweating. They have an appointment in the Twilight Zone.

The shift foreman and his supervisor arrive at the control room several seconds after the turbine trip. They begin to help the control room operators.

Faust, studying the blinking, buzzing, ringing control panels, discovers that the auxiliary feedwater system valves are closed. He opens the two valves from the control room. Eight minutes after the turbine trip, water finally begins to surge into the massive, drying steam generators. But the pressurizer gauge is still off the high end of the scale.

Ten minutes into the accident, the emergency core cooling system pumps are throttled down still more.

Steam generator placed into reactore building while Unit 2 was under construction.

As water finally begins to cool the steam generators, an incredible event occurs: the malfunctioning control room gauge indicating a high water level in the pressurizer suddenly begins to drop. The nuclear workers realize with horror that they have been led by a bad gauge!

Six and a half minutes after the emergency core cooling system pumps were first throttled down, Frederick throws them back on.

Despite this action, the zirconium tubing that holds the uranium fuel has already begun to bend and melt in the atomic steam. When water from the emergency core cooling system hits the melting core, the zirconium in the tubing combines with the oxygen in the water and the air, producing hydrogen. Some of the hydrogen blocks the cooling channels within the core, while still more gas particles rise to the top of the reactor's pressure vessel, forming a bubble.

The relief valve on top of the pressurizer remains open and water from the emergency core cooling system follows the rest of the primary coolant into the wastewater storage tank. The water from the emergency core cooling system, poured directly through the bubbling core, is highly radioactive and contains particles of uranium.

Fifteen minutes into the mishap, the wastewater storage tank is filled. This tank is not designed to hold as much water as is now pouring into it. A rupture disc on its side blows, and the water from the primary loop splashes onto the floor of the containment building. A sump pump drains this radioactive water into a nearby auxiliary building, where it soon fills the tanks and then overflows. The auxiliary building floor and walls are not meant to hold radioactive material. Radioactivity will soon be vented into the atmosphere.

Meanwhile, the temperature of the nuclear core continues to rise, alarming the increasing number of men in the control room. They are not aware that hydrogen bubbles are beginning to block the core's cooling channels.

Outside the control room, the Susquehanna River continues its lazy journey around Three Mile Island. The people of the Susquehanna Valley are beginning to wake. Soon they will greet a new day.

2.

Nuclear neighbor: Civil engineer Bill Whittock was awakened by the sudden blast of steam signalling the start of the meltdown on Three Mile Island.

Bill Whittock sits bolt upright in his bed, his eyes wild. A sudden, jet-like roar has broken his sleep. Instinctively, Whittock gazes across the Susquehanna River where the nuclear power plant on Three Mile Island looms out of the darkness. The plant is illuminated by many floodlights.

Living directly opposite Three Mile Island on the river's west bank in the tiny borough of Goldsboro, Whittock has a splendid view of both nuclear reactors and all four mammoth cooling towers. The roaring sound continues. Now out of bed, staring through his window, Whittock sees the huge, white column of steam rising above the atomic power plant. Soon the steam seems to be as high as the tips of the 372-feet-tall cooling towers. From his perspective of the island, the cloud of steam appears to be shooting from the round reactor building of Unit Two. Though he has heard steam issuing from Three Mile Island at least a half dozen times before, Whittock is still not accustomed to his neighboring nuclear power plant.

Whittock walks from his bedroom, down the dark stairway. He is alone. His wife and daughter are touring Alaska. Because it is unusually warm for four in the morning, he opens his front door. Standing inside his screen-enclosed front porch, Whittock watches the steam rising. The loud whistle of the escaping vapor does not subside. There is little wind. The man-made cloud lingers lazily over Three Mile Island. Bill Whittock's neighbors, living in cottages on either side of a small marina, remain asleep.

It's much the same story on the east shore of the Susquehanna. Mr. and Mrs. C. Daniel Engle live directly opposite the nuclear plant on the Middle town side. They sleep peacefully.

But less than three quarters of a mile away from the Engle house, Sue Showalter stirs restlessly and awakens. The loud blast of steam is a familiar sound to her and to most of her neighbors living near the island. She has heard unexpected noise in the past from the nuclear plant, so she tries to ignore the steam blast.

Living near the Harrisburg International Airport, the Showalters have learned to contend with many loud noises. Sue Showalter has even learned to identify the origins of many of the sounds: if a whistle begins softly and builds to a thunder, it comes from a plane with business at the airport; if, however, the din is sudden, with no buildup, and roars like an angered bull, it is steam escaping from Three Mile Island. At any rate, she tells herself, this sound in the night is nothing to worry about. Her husband, Earl, does not rouse. Soon the roaring stops, and Sue relaxes, but sleep is delayed by one more loud eruption of steam.

Across the river, Whittock is still standing on his porch watching a cloud of steam rising into the dark sky. He hears nothing. He estimates the roaring has lasted five minutes. After returning into his darkened house and trudging up his stairway, he hears a sudden whistle from the power plant.

"The old thing's popped off again," he tells himself. "Routine." Then he falls to sleep.

3.

Three miles north of the nuclear island, off Middletown Square, sits Jack and Jean's 7-11 store, open 24 hours a day. At 4:00 am two people are inside. One is Kathy Henning, who prepares coffee for the morning rush, which begins around 5:30. The other is Charlie Starliper, just killing time. He pictures himself doing "absolutely nothing" at the same time steam is pouring from the nuclear plant. Neither person is aware of anything wrong on Three Mile Island. They're too far away to hear the blast of the pressurizer.

A few blocks from the 7-11, in the Middletown Police Station, Carry Murray sits in a small communications room. It has been a normal Middletown night -- slow. The borough's three police cruisers, now patrolling, report nothing to Murray about hearing loud blasts from the atomic power plant. No one phones about anything out of the ordinary occurring on Three Mile Island. He knows many of the townspeople who work at the atomic plant. He is a part-time student at Harrisburg Area Community College. He occupies the quiet hours with a commercial art homework assignment.

Meanwhile, the Pennsylvania State Police, charged with patrolling the commonwealth's backloads and hamlets, has no cruiser sufficiently close to be aware of the whistle from Three Mile Island. The command center of the Pennsylvania Emergency Preparedness Agency, which would coordinate with the State Police in the event of an emergency, is located beneath the Commonwealth Department of Transportation building in Harrisburg. No warning is received there about any trouble on Three Mile Island.

The Dauphin County Courthouse, also in Harrisburg, houses the County Emergency Preparedness Office. At four o'clock on this critical morning, the night crew has received no phone call from Three Mile Island.

Kevin Molloy, Director of Dauphin County Emergency Preparedness, is asleep at home in Middletown within eyesight of the nuclear power plant.

Not far from where Molloy sleeps, Michael J. Donelan, Jr. is working the "back shift" in a parts warehouse on Three Mile Island. He's preparing parts for nuclear repairmen -- a routine shift. Suddenly, he hears the scream of the pressurizer valve blowing open. Having heard that sound many times before while working on the island, he's sure he knows its cause. Within seconds, though, as if to confirm his intuition, he hears the control room operator announce over the plant intercom that there's been a turbine trip.

With nothing better to do at the moment, Donelan walks outside and watches steam blowout from somewhere near Unit Two's reactor building.

The white cloud rises above the cooling towers, practically straight into the air, on this windless night. After hearing four blasts, Michael Donelan returns to his night shift, sorting parts in a warehouse on Three Mile Island.

4.

Time is playing tricks in the control room of Unit Two. For the men working there at 6:20 am, time seems to have gone haywire. First the stream of time increased its speed, then it stood still and reversed.

Control room operator Craig Faust was probably the first to be tricked by time this morning. When the reactor had scrammed at 4:00 am, Faust had imagined it had taken him only a minute to open the auxiliary feedwater valves, sending much needed coolant to the drying steam generators. Actually, the precautionary operation had required eight minutes.

Then there was the problem with the computer's alarm printer. When the reactor had first scrammed, hundreds of alarms rang and buzzed and flashed. Normally when an alarm sounds, a control room operator moves to the computer's printout that puts the problem in writing. But this morning so many alarms had come so rapidly that the computer's typewriter printout had quickly fallen behind. The control room operators had heard a staggering number of alarms, but had no idea why they rang. Faust had wished at 4:00 am that he could throwaway the alarm panel. Now, at 6:20 am, the computer is just getting around to deciphering the alarms that had sounded at 5:00 am. The operators must now wait ten minutes, until 6:30 am, to see the alarm printout for 5:10 am, when the reactor's coolant pumps had begun to shake so violently that they had to be closed.

As well as having serious computer and mechanical problems, the control room operators are having difficulties interpreting important gauges. To better understand of the complexity of the situation now being encountered in the control room, a brief description of a pressurized water reactor is in order.

Detail of original engingineering schematic of TMI's Unit 2, showing reactor containment building with reactor, pressurizer, and steam generators. Click on drawing or here to view full schematic with fuel storage and turbine building.

Unit Two's reactor on Three Mile Island has two main water systems.

The primary water system passes through and cools the nuclear core, while the secondary water system transfers heat away from the primary system by way of two 79 feet tall steam generators. The secondary system in turn drives a huge turbine that generates electricity.

When everything is working the way it's supposed to, the primary and secondary water systems never blend, but only transfer heat within the steam generators. This is because the primary system is very radioactive, having come in direct contact with the zirconium clad uranium, and also because the primary system is normally pressurized to 2,155 pounds per square inch, giving it much greater density and a higher boiling point than the secondary water system. For this reason, Unit Two is called a pressurized water reactor.

The reactor pressure vessel, the primary water system, the steam generators and the secondary water system excluding the turbine -- are all enclosed in the reactor containment building. This building is 200 feet tall. People standing in the airlock doorway feel dwarfed. When the reactor was under construction, workers in the containment building could look up into the dome and see clouds floating far overhead inside the building.

Now it's not so easy to see what's going on in the reactor containment building. The four feet thick reinforced concrete walls, and their contents, of course, cannot be seen from the control room of Unit Two. To control the reactor, the operators must rely on the plant's computer, some 740 miles of electrical wiring, many sensing devices and gauges, 1,104 silver-indium-cadmium alloy control rods and mechanically operated valves and pumps.

When the main reactor coolant pumps had been shutdown at 5:10 am, the men in the control room had begun working to obtain natural circulation of the primary coolant. Now, at 6:20 am, they hope the core will soon begin to cool using a convection method, whereby the hotter water is pulled to the top of the pressure vessel, then pushed out its "hot legs" to repeat the process. But at 6:20 am, the men in the control room are worried because gauges indicate the primary coolant isn't flowing. One thing the gauges do not indicate is that hydrogen is blocking the reactor's cooling channels.

The primary system has two loops, lettered in unimaginative but literal engineering terms, "A" and "B" which carry away heated water from the atomic core to the steam generators. Through these loops, hot water passes from the top of the reactor pressure vessel to the respective steam generators, A and B. Where the water leaves the core, on its way to the steam generators, are thetwo so-called "hot legs," A and B. And where the water flows back into the bottom of the reactor are two "cold legs," which are not surprisingly, called A and B.

At 6:10 am, Loop A's hot leg temperature had increased off the high end of the scale. This means that the temperature there is greater than 620 degrees Fahrenheit. But the dozen or so men now in the control room do not know how much greater. When they ask the computer for Loop A's hot leg temperature -- using an electronic display thus bypassing the lagging printout -- they receive nothing but question marks. The top of the core is hotter than the computer is programmed to display.

Detail of Unit 2 reactor coolant system. The reactor (center) is connected to two 79-foot-tall steam generators to its left and right. The pressurizer here is hidden behind the steam generator on the right. Chick on drawing or here to view full schematic.

In the control room at 6:20 am are Bill Zewe, a shift supervisor, and Fred Scheimann, a shift foreman; both had joined Faust and Frederick several seconds after the 4:00 am trip. George Kunder, Unit Supervisor for Technical Support; Brian Mehler, a shift supervisor scheduled to begin work at 7:00 am, and an assortment of control room operators and technicians are also present. They are desperately trying to deduce what is wrong with Unit Two's nuclear core. At the same time, they must try to prevent the situation from worsening.

The most vital information that they do not have is that the primary loop's electromatic relief valve on top of the pressurizer is jammed open. Primary coolant continues to pour from the stuck valve two hours and twenty minutes after it should have closed!

The men in the control room have not completely overlooked the possibility that the pressurizer valve is open. There are several instruments that should tell them this. The problem is, those instruments are useless. One indication is a "command signal" light on the pressurizer valve's control switch. This had been installed almost one year earlier, on March 29, 1978, when the computer's logic circuits had failed to give an electronic command for the valve to open. Strangely, however, this light does not indicate whether the valve is open or closed -- it simply reports whether the computer has given the valve a command. And this morning, the computer did command the pressurizer valve to close, and the command signal light did change. But the valve had jammed, and no control room indication exists to tell the operators that the valve remained open.

The second indication for determining the position of the pressurizer valve is the temperature of the valve's steam escape pipe. Operating procedures are such that the pipe's normal operating temperature should be 130 degrees F. Furthermore, procedures say that if the temperature of the valve's steam escape pipe is greater than 200 degrees F., an open valve should be suspected at once.

The problem is, since the reactor had begun commercial operation in December, 1978, the pressurizer valve has been leaking slightly, as have other, smaller valves that share the same steam escape pipe. The plant's owner, Metropolitan Edison, for tax and regulatory reasons, had made a corporate decision to operate Unit Two despite this slight malfunction. The federal and state regulators had eagerly cooperated with this decision. In essence, in order for Met-Ed to charge its ratepayer's for electricity from Unit Two, the reactor had to be in operation and declared "used and useful" by the utility and the state Public Utility Commission. Delaying the start of the reactor's electrical generation to fix these apparently small problems would have cost the utility and its investors millions of dollars.

Engingineering schematic of TMI's Unit 2's crucial pressurizer. The stuck safety valve is on the top. Click on drawing or here to view full schematic.

So the temperature of the steam escape pipe has, since Unit Two began operating, generally been 180 degrees F., or fifty degrees hotter than the 130 degrees it should have been.

To add to this confusion, the control room operators know that the steam escape pipe should be very hot. This pipe carries steam from the same valve through which primary coolant, heated to more than 550 degrees F., had first whistled at the time of the turbine trip.

Twice this morning of the accident, Frederick and Zewe have read the temperature of the steam escape pipe. Once, at 4:20 am, then an hour later, at 5:20 am, the computer's electronic display had informed the men that the pipe's temperature was about 230 degrees F.

Here is how time is playing a trick with Ed Frederick and Bill Zewe: each man pictures the hot pressurizer relief valve in his mind as he asks himself, "How much time should it take the steam escape pipe to cool after the pressurizer valve has opened?" The 230 degree F. temperature does not alarm them.

Meanwhile, primary coolant continues to bleed through the stuck valve, out the steam escape pipe, into the drain tank with a blown pressure disc, then onto the containment room's floor.

At 4:38 am, an auxiliary building operator had hailed Frederick over the plant intercom and informed him that a panel in the auxiliary building indicated there was more than six feet of water in the containment building's sump. Frederick already knew that the containment building's sump pumps had been activated shortly after the reactor scram, but those sump pumps normally start once every shift so he was not concerned. Fredereck knew, too, that with both sump pumps operating, the water level in the containment building shouldn't be as high as it was -- unless something was leaking.

So Frederick instructed the auxiliary operator at 4:38 am to change the path of the containment building water from two low auxiliary building sump tanks to a tank that is at a higher elevation. At the same time, Frederick stopped the sump pumps. Since water cannot run uphill, these actions should have prevented water from passing into the auxiliary building. But the auxiliary operator had not changed the path of the water as Frederick had instructed him to do, so the containment water continues to drain downhill, into the auxiliary building sump tanks. The men in the control room do not know about this mishap, either.

Of much more concern to the men in the control room is the origin of the water leak. Not only does a high water level in the containment building signal a leak somewhere in the massive system, but it also means pressure is escaping. The primary coolant is never supposed to boil during normal operation. At about 5:00 am this morning, however, the pressure had dropped low enough for the coolant to reach saturation point. In simple words, it boiled. Joining the hydrogen in the reactor cooling channels, steam has begun to alternately block the primary coolant, then collapse under the pressure of the system.

When the water started boiling at 5:00 am, the reactor coolant pumps began shaking violently. Loud rumbles were heard in the control room. The same way an outboard motor stirs water behind it, the pumps had begun to stir up air bubbles. The delicate rotors of the reactor coolant pumps ran the risk of destroying themselves on air bubbles. This phenomenon, known as cavitation, forced the men in the control room to shutdown all four reactor coolant pumps. When that had happened, the uranium core was three quarters exposed to the atmosphere.

Time plays tricks: Photo of actual Unit 2 control room computer printer. Essentially an old-fashioned IBM Selectric typewriter, the printer quickly fell behind and then failed the morning of the accident, leaving operators to guess what was going on in the reactor.

With practically no help from the computer, the men in the control room try to solve the problem. They labor over the information fed them by the malfunctioning gauges and the lagging computer print out. What must be happening inside the reactor? they asked themselves. First of all, they identify the symptoms: There's lots of water in the containment building, and hardly any pressure in the primary loop. First to their minds come thoughts of a leak in one of the steam generators.

Faust says he believes that the problem is with steam generator B, because of difficulties he is having maintaining the water level there. Actually, water is not flowing into steam generator B because of a leak but because hydrogen and steam are blocking the cooling channels leading to the generator. Faust points out that when he had discovered the auxiliary feedwater valves closed at 4:08 am, he had opened them quickly, pumping 60 degree F. water into the drying steam generators. Now Faust says that he fears steam generator B has suffered from thermal shock, the result of cold water hitting a tremendously heated piece of equipment. This, Craig Faust reasons, is the cause of the water on the floor of the containment building.

But at 5:27 am, when Faust had isolated steam generator B by valving off all water to it, nothing was helped. In fact, valving off steam generator B made matters much worse. Only steam generator A continued to act as a heat sink, and the primary coolant heated more rapidly. And just ten minutes ago, at 6:10 am, Loop A's hot leg temperature had risen so high that it went off the scale.

The other men in the control room are less certain than Faust that there exists a leak in the steam generators. They fear a leak somewhere in the vast system of the primary loop's plumbing. Some of the men gather in a circle around Ed Frederick and Bill Zewe.

The computer, its alarm printer, and most of the important gauges in the control room have become obstructions to the men instead of the extensions they were designed to be. If only the men could see through the four feet thick concrete walls into the containment building; if only they could use their eyes instead of these clumsy instruments to see the source of the splashing primary coolant. The temptation is great to send men inside the containment building for a look.

Only one radiation alarm has sounded in the control room. That had happened almost two hours ago, at 4:25 am. Then, an alarm indicating an abnormally high amount of radiation in the containment building had sounded. But the alarm has a very low set point, and normally sounds with every reactor trip. This particular alarm was dismissed as insignificant.

At about 5:45 am, Three Mile Island's radiation protection and chemistry specialist, Richard Dubiel, was asked by supervisor George Kunder to attain a sample of the reactor building's atmosphere, from which a reading would help determine whether men could be sent inside. Unit Two's containment building air samples are drawn through lines connected to a sample board in Unit One's laboratory. This morning, the process had been slowed because monitors in the Unit Two reactor building were underwater. Dubiel informed Kunder that it would take at least 45 minutes to get a valid air sample.

Meanwhile, at 6:18 am, Bill Zewe had requested the pressurizer relief valve's steam escape pipe temperature reading for the third time on the computer's electronic display. It was about 230°F. Zewe was not alarmed because he knew that the temperature of the primary coolant was at least 620°F., and he had assumed that the steam escape pipe would have to be at least 300°F., or greater, if the valve on top of the pressurizer was open.

At 6:22 am, the men in the control room are brainstorming. They must find the solution. The temperature of Loop A's hot leg is off the scale. Loop B's hot leg is not far behind.

In desperation, Brian Mehler, the shift supervisor scheduled to begin work at 7:00 am, suggests to Fred Scheimann that they should try isolating, or cycling, the pressurizer's electromatic relief valve. Standard procedure does not allow for guessing about relief valves, but Brian Mehler cannot think of anything else to do. Scheimann walks over to the pressurizer relief valve's control plunger and manually commands the valve to open, then close. The red command signal indication light flashes on, then blinks off. Meanwhile, in the containment building, the pressurizer relief valve finally closes.

Instantly Ed Frederick notices that the pressure of the primary coolant has begun to rise, at the same time the containment building air pressure drops. Mehler has found the problem! Temporarily, the men in the control room are jubilant. Within five minutes, however, the computer's alarm printer breaks down completely. The alarm printer is one hour and twenty five minutes behind. The alarm function of the computer is transferred to an auxiliary printer while a technician works on the malfunctioning printer.

At 6:28 am, the temperature of Loop B's hot leg goes off scale. Finally realizing that steam generator B is not leaking, Faust rushes to fill it with coolant. Within ten minutes, Bill Zewe has received an erroneous boron level reading from the primary coolant. Boron is added to the coolant to moderate, or slow, the nuclear chain reaction. Somehow diluted with distilled water, the bad sample indicates to Zewe that little boron is now is the primary coolant. Zewe orders an emergency boration of the primary loop.

Less than three hours after the accident's genesis -- at 6:45 am to be exact - radiation alarms sound on the control room's radiation monitor panel. Radioactive water has begun to overflow the auxiliary building's sump tanks, spilling onto the floor of the unshielded structure. Airborne radioactive particles begin to be vented into the atmosphere. About the same time, the men in the control room receive word from Richard Dubiel that the containment building's atmosphere is dangerously radioactive. No one can be sent inside the reactor building.

Faust now returns steam generator B to service. The men in the control room are hoping to restart the reactor coolant pumps. But when Frederick gives reactor coolant pump 1A the command to operate, it trips and fails to operate.

Two minutes pass, then the technician working on the alarm printer announces that there has been another malfunction. This time, all unprinted alarms stored in the computer's memory from 5:13 am until now, 6:48 am, are erased!

By 6:52 am, Frederick is attempting to start reactor coolant pump 2A.

But, as was the case with reactor coolant pump 1A, this second coolant pump refuses to start. Ed Frederick tries to turn on reactor coolant pump 1 B. Like the two before, pump 1 B will not operate.

In the control room everybody begins to realize that they are far from out of the woods. They still do not realize that the core has partially melted, that hydrogen was produced by the melting zirconium fuel rods, that the gas is only beginning to block the core's cooling channels. Finally, at 6:54 am, Frederick starts reactor coolant pump 2B. This pump works.

5.

But, within a minute, one of the technicians is on the phone to the Pennsylvania Emergency Management Agency and to Dauphin County Emergency Preparedness. Both agencies are told that Bill Zewe has declared a Site Emergency at 6:55 am on Three Mile Island. Nearly three hours after the initial trip, the men in the control room of Unit Two have begun to call outside for help.

In rapid succession another bad event occurs. Since the electromatic relief valve has been closed now for more than a half hour, pressure in the primary loop builds to the point where the shut off of the emergency core cooling system automatically occurs. Much needed emergency core cooling system water is no longer being poured through the melting core.

Meanwhile, Craig Faust proceeds to isolate steam generator B again, taking it out of service. The same way a frightened pilot in a nose diving plane will sometimes pay too much attention to one control, Faust incorrectly believes the ills of the moment can be cured if steam generator B can only be isolated. Three Mile Island's station manager, Gary Miller, arrives in the control room at 6:55 am.

Miller announces that he is now in charge of the control room, and calls for a conference of senior personnel in the shift supervisor's office, next to the control room.

By 7:10 am, the men in the control room are trying to contact the Nuclear Regulatory Commission's regional headquarters in King of Prussia, Pennsylvania. No one answers the phone at the NRC.

At 7:13 am, the pressurizer's electromatic relief valve is again opened from the control room. Bill Zewe is attempting to lower the primary loop's pressure enough for the emergency core cooling system to resume pumping water over the core.

Gary Miller, meanwhile, breaks away from his conference to speak with instrument and control supervisor Ivan Porter. Following Miller's instructions, Ivan Porter goes to the cable spreading room with a millivolt meter. Inside the cable spreading room, where the unit's electrical connections are organized, Porter locates wires leading from the hot leg thermocouples. Porter touches the millivolt meter to the thermocouple connections and learns that the hot leg temperature from the reactor is now 2,400° F.

Ivan Porter's information disturbs Gary Miller. Although the nuclear industry claims that this has never happened previously inside a commercial nuclear power plant, Unit Two might soon reach the temperature where nothing can be done to cool the reactor. The uranium core will then heat uncontrollably, until it reaches a uniform, molten temperature of five thousand degrees Fahrenheit.

Gary Miller, the Three Mile Island station manager, does not give the hot leg temperature information to the control room operators. Instead, he declares a General Emergency on Three Mile Island at 7:24 am.

Almost everything possible seems to have gone wrong this morning in the control room of Unit Two. The very worst possible event, a total core meltdown, might be imminent.

Gary Miller must wonder whether time will be on his side.

--Bill Keisling

Posted March 28, 2011

The Meltdown

A novelBuy paper or ebook editions

Buy a paper copy $15 >

Buy for all ebook readers - $7.99

Copyright © 2011 - 2014 yardbrd books

info@yardbird.comblog comments powered by Disqus